How To Make Semiconductors Production More Energy Efficient?

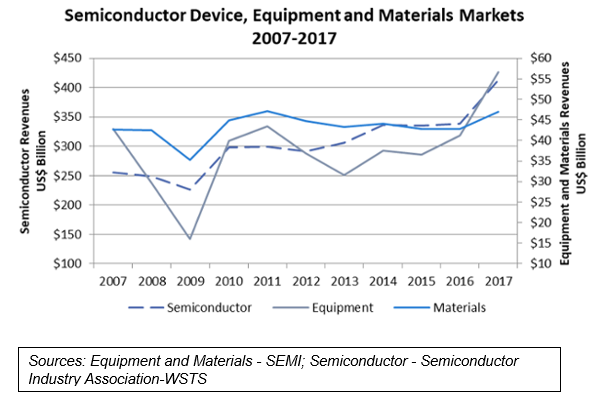

The single most expensive requirement in semiconductors production is undoubtedly a clean and continuous supply of electricity. Ensuring a continuous supply is thus vital for the semiconductor fabrication plants. The global semiconductor business is ever growing, with the continual increase in the demand for the electrical appliances.

The world population hugely depends on the consumption of electrical appliances. Let alone consider the single case of the tremendous growth in the demands of mobile handsets in the recent decade, if you choose to overlook other electronic items.

Why is more energy required in the semiconductor industry?

In this industry, the units are measured in nanometres so the machinery utilized in the semiconductor industry has to be very precisely calibrated. Now a slight fluctuation in the voltage will cause a major impact on the quality, precision and ultimately lead to huge loss in production. But this is certainly not the single major cause why huge and constant demand for electricity is required in the semiconductor industry.

One more important thing to consider is that a power event or blackout has major financial consequences. Failure in power supply also presents major risks to the humans operating the machines. Thus, increasing the liabilities and insurance. With the ever-increasing demand for the higher level of penetration of electronic goods in the global market and so much riding on the innovation to fulfill it, the need is there to keep the economics of the production right.

But we must not forget that despite all this we need to consider and look for all opportunities available to minimize the consumption of energy as much as we can for lowering its impact on the environment.

How can energy consumption be lowered?

To optimize the energy consumption one of the solutions are the use of Electric UPS for critical power applications. This ensures clean and continuous power uptime for reliable and quality production with up to 30% energy savings.

EU has recognized the major impact of high usage of energy on the finances of the industries and on the environment. So, they aim to lower it by 20% by 2020 without decreasing the productivity and compromising on the quality of the production in the chip industry.

Comments

Post a Comment